The story of DongCheng begins back in 1987 in the repair of power tool motors and the sale of parts. The founder of DongCheng Tools, Gu Zhiping, wanted to do more and aspired to create an entirely original brand.

A Story of Striving for Excellence and Continuous Improvement

The story of DongCheng begins back in 1987 in the repair of power tool motors and the sale of parts. The founder of DongCheng Tools, Gu Zhiping, wanted to do more and aspired to create an entirely original brand.

In 1995, he achieved this vision by starting a new electric motor tool production range under the name Oriental Power Tools.

In 1997, the company officially applied to trademark the name “DongCheng a combination of 2 Chinese words where “Dong” means oriental, and “Cheng” means succeed.

By the start of the century, DongCheng became the preferred power tool and parts brand in China.

In 2001, “Jiangsu DongCheng Power Tools” became the registered trade name and the company began to steadily grow – taking up more space in the industry by turning into a power tool manufacturer rather than simply supplying power tool parts.

2002 marked the launch of DongCheng’s first three power tool products – the SIM-FF-100A Angle Grinder, the Z1C-FF-20 Electric Hammer, and the Z1E-FF-110 Electric Marble Cutter. All of which have become a permanent fixture in the DongCheng catalog.

This kickstarted the production of more than 40 different DongCheng power tools and established the company as a comprehensive and professional power tool manufacturing enterprise.

DongCheng quickly made investments in research and development to improve on the already impressive product line.

By 2013, DongCheng was ranked number 1 in the Chinese power tools market and set up its official overseas sales division to jumpstart expansion into a global market.

This is also when the company took its first steps in creating its lithium battery-powered power tools.

In 2015, DongCheng established its proprietary test laboratory – a state-of-art facility that takes up 4,000 square meters of area and features the latest technology to ensure effective quality testing.

The DongCheng laboratory received its accreditation from the China National Accreditation Service (CNAS), Intertek testing, and the TUV – ensuring its expert capabilities.

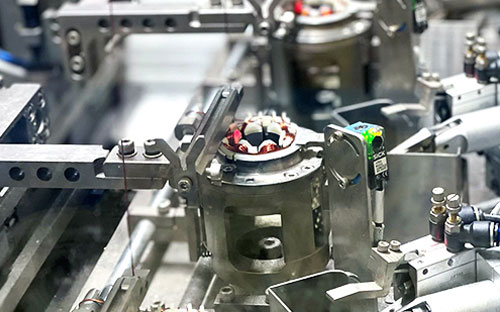

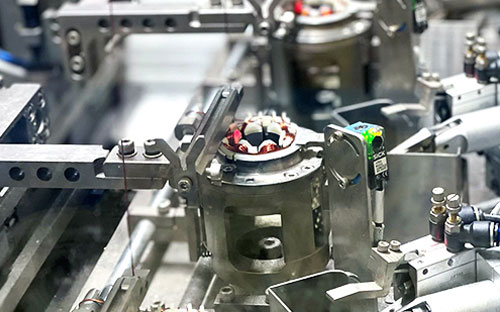

2018 marked the operation of the company’s third, and largest, production base with a fully automated assembly line to drastically improve production speeds.

At this point, the company’s manufacturing process covered AC and DC products, brushless motor manufacturing, mold manufacturing, aluminum processing, injection molding processing, complete machine assembly, and so much more.

The annual output of the DongCheng production line could easily have exceeded 20 million units.

The Shanghai Europe-US Regional Sales Center was established in 2020 as a pioneering step to expanding the DongCheng market into Europe and the US.

The Shanghai research and development center was also introduced at this time and worked in conjunction with the Nantong (Jiangsu), Hangzhou, and Suzhou centers to further the company’s investment in innovative technology and market recognition.

This was the start of a commitment to shaping the DongCheng company into an internationally renowned supplier of cutting-edge power tools and superior quality.

By 2021, DongCheng reported a sales revenue of close to RMB 6 billion despite the debilitating effects of the COVID-19 pandemic on most industries.

DongChen maintained its steady development by investing more time, energy, and capital in its research and development centers to improve its product range.

The company also invested RMB 100 million to upgrade its manufacturing capabilities for the building of automated smart-production sites.

DongCheng accelerated its brand-building efforts – which are still bearing the fruits of success today.

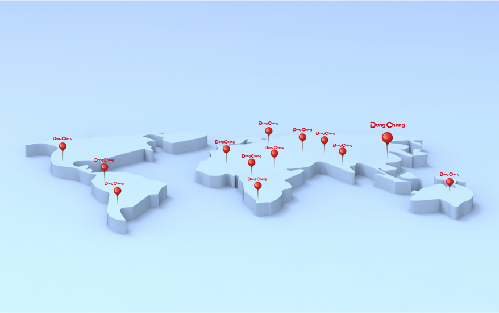

2024, Hit record sales of 6.468 billion yuan,constantly12 years dominating the Chinese market. Exporting to over 80 countries.

2025, Celebrating 30 years of sustained focus on power tools and equipment with excellence and innovation.

For DongCheng, there is no final form. We believe in continuous improvement and innovation.

The values of discipline, integrity, and passion of DongCheng have ensured a company history metered by perseverance and a willingness to evolve.

The future of DongCheng involves a focus on sophisticated engineering, ambitious designs, and the basic desire to move forward, not only for the company itself but for the world it caters to.

The story of DongCheng begins back in 1987 in the repair of power tool motors and the sale of parts. The founder of DongCheng Tools, Gu Zhiping, wanted to do more and aspired to create an entirely original brand.

In 1995, he achieved this vision by starting a new electric motor tool production range under the name Oriental Power Tools.

In 1997, the company officially applied to trademark the name “DongCheng a combination of 2 Chinese words where “Dong” means oriental, and “Cheng” means succeed.

By the start of the century, DongCheng became the preferred power tool and parts brand in China.

In 2001, “Jiangsu DongCheng Power Tools” became the registered trade name and the company began to steadily grow – taking up more space in the industry by turning into a power tool manufacturer rather than simply supplying power tool parts.

2002 marked the launch of DongCheng’s first three power tool products – the SIM-FF-100A Angle Grinder, the Z1C-FF-20 Electric Hammer, and the Z1E-FF-110 Electric Marble Cutter. All of which have become a permanent fixture in the DongCheng catalog.

This kickstarted the production of more than 40 different DongCheng power tools and established the company as a comprehensive and professional power tool manufacturing enterprise.

DongCheng quickly made investments in research and development to improve on the already impressive product line.

By 2013, DongCheng was ranked number 1 in the Chinese power tools market and set up its official overseas sales division to jumpstart expansion into a global market.

This is also when the company took its first steps in creating its lithium battery-powered power tools.

In 2015, DongCheng established its proprietary test laboratory – a state-of-art facility that takes up 4,000 square meters of area and features the latest technology to ensure effective quality testing.

The DongCheng laboratory received its accreditation from the China National Accreditation Service (CNAS), Intertek testing, and the TUV – ensuring its expert capabilities.

2018 marked the operation of the company’s third, and largest, production base with a fully automated assembly line to drastically improve production speeds.

At this point, the company’s manufacturing process covered AC and DC products, brushless motor manufacturing, mold manufacturing, aluminum processing, injection molding processing, complete machine assembly, and so much more.

The annual output of the DongCheng production line could easily have exceeded 20 million units.

The Shanghai Europe-US Regional Sales Center was established in 2020 as a pioneering step to expanding the DongCheng market into Europe and the US.

The Shanghai research and development center was also introduced at this time and worked in conjunction with the Nantong (Jiangsu), Hangzhou, and Suzhou centers to further the company’s investment in innovative technology and market recognition.

This was the start of a commitment to shaping the DongCheng company into an internationally renowned supplier of cutting-edge power tools and superior quality.

By 2021, DongCheng reported a sales revenue of close to RMB 6 billion despite the debilitating effects of the COVID-19 pandemic on most industries.

DongChen maintained its steady development by investing more time, energy, and capital in its research and development centers to improve its product range.

The company also invested RMB 100 million to upgrade its manufacturing capabilities for the building of automated smart-production sites.

DongCheng accelerated its brand-building efforts – which are still bearing the fruits of success today.

2024, Hit record sales of 6.468 billion yuan,constantly12 years dominating the Chinese market. Exporting to over 80 countries.

2025, Celebrating 30 years of sustained focus on power tools and equipment with excellence and innovation.

For DongCheng, there is no final form. We believe in continuous improvement and innovation.

The values of discipline, integrity, and passion of DongCheng have ensured a company history metered by perseverance and a willingness to evolve.

The future of DongCheng involves a focus on sophisticated engineering, ambitious designs, and the basic desire to move forward, not only for the company itself but for the world it caters to.